Lice Memory Tool Research Design

Flies, Lice and Worms are a major concern for woolgrowers. We have developed tools for woolgrowers to manage these risks.

The three most common parasites of sheep are flies, lice and worms, including liver fluke. Parasites are a major concern for woolgrowers because of their health, welfare and productivity impacts on sheep. Together they are estimated to cost the industry close to $700 m per annum in treatment, prevention and production costs.

To support woolgrowers in the prevention and treatment of parasites for sheep, the ParaBoss suite of resources have been developed for each major parasite risk.

Funded by AWI and Meat and Livestock Australia (MLA) and delivered by the University of New England with industry oversight, ParaBoss is the premier Australian source of free, independent, practical parasite management information for woolgrowers and their advisors. It includes FlyBoss for flystrike management, LiceBoss for lice management and WormBoss for worm management. The FlyBoss, LiceBoss and WormBoss websites are sources of detailed management information and regional programs that assist woolgrowers in managing the major parasite risks for sheep on their properties. The information and resources have been developed by expert panels of parasitologists and veterinarians from across Australia. Find out more about ParaBoss and its suite of three products (WormBoss, LiceBoss and FlyBoss) here.

Subscribe to ParaBoss News, the twice monthly free email newsletter with state outlooks on the current state of sheep parasites as well as feature articles and the quick quiz to test your knowledge of sheep parasites.

Join ParaBoss on Facebook at www.facebook.com/paraboss.com.au to see regular posts on flystrike, lice and worm control.

All new parasite information from AWI funded R, D & E programs and others flow through to the ParaBoss suite of websites, which together form an encyclopaedia of everything you need to know about managing sheep parasites.

FLY MANAGEMENT

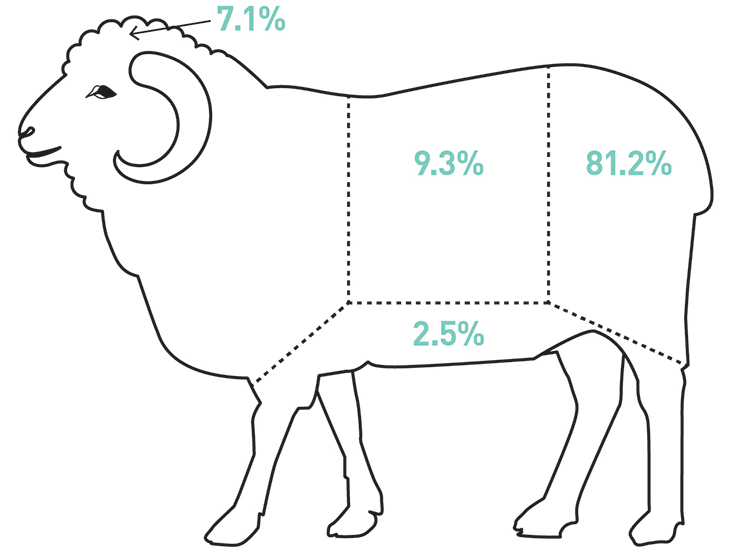

Flystrike, caused largely by the Australian sheep blowfly, is a major risk and disease for the sheep industry costing it over $173 million each year due to control, treatment and lost production costs. Breech and body strike are the two most common forms of flystrike. Over 80% of flystrike occurs in the breech area of the sheep (breech flystrike).

Flystrike locations on sheep. Adapted from Heath A.C.G., Bishop D.M. (1995). Flystrike in New Zealand Surveillance, Volume 22 (Jan), Issue 2, pp 11-13.

The threat from increasing blowfly resistance to the commonly used chemicals applied for prevention of flystrike means woolgrowers need effective long-term fly control strategies to minimise the risk of chemical resistance. They do this by only using chemicals when absolutely necessary and implementing integrated pest management strategies that incorporate non-chemical controls such as mulesing with anaesthetic and analgesia, genetic selection and timing of shearing and crutching.

The website FlyBoss provides information and tools to assist woolgrowers in developing a flystrike management plan tailored to each individual sheep enterprise. It includes the latest information on how to:

- Reduce the risk of flystrike through management and breeding

- Treat flystrike outbreaks

- Slow the development of blowfly chemical resistance.

Through FlyBoss, woolgrowers have access to tools and resources to help them:

- Check the flystrike risk and optimise treatment time and selection for their location and sheep types

- Compare management systems for flystrike control

- Find information on fly chemical treatments, their cost, withholding periods and export slaughter intervals

- Develop a blowfly resistance management strategy tailored to their property

- Use the WoolRes tool to assess the risk of chemical residues in the wool clip.

A new tool, released on FlyBoss in September 2020, is the 'FlyBoss Risk Simulator' tool, created by the University of Tasmania. It combines and builds on existing FlyBoss tools and enables woolgrowers to review their current flystrike prevention program and simulate possible management and breeding changes that could reduce the risk of both body and breech flystrike in their particular location.

Current and Recent AWI Projects

AWI has a comprehensive R & D program to fund research and develop technologies to prevent or reduce the impact of flystrike on the Australian sheep flock. The key pillars of AWI investment in flystrike R & D relate to:

- Improved management practices to advance lifetime welfare, including advances in non-invasive flystrike management practices such as crutching, jetting, accelerated shearing, short joining and lambing, worm control, nutrition and improved fly control such as improved delivery of current chemicals, development of new chemicals and blowfly vaccine development.

- Development of tools and information to support breeding and selection of naturally resistant sheep as a long-term solution for preventing flystrike.

- Support for breech modification procedures to improve lifetime resistance of sheep to flystrike.

- Improved provision of analgesia and anaesthesia to alleviate pain associated with surgical husbandry procedures.

- Education, extension and promotion activities to encourage adoption of best practice strategies to improve the lifetime welfare of sheep and support transparency in the supply chain.

For more information on the AWI flystrike program, go here.

LICE MANAGEMENT

Lice are estimated to cost the Australian sheep industry $81 million per year in treatment, prevention and production costs, including reduction in fleece values.

For many woolgrowers, lice control relies on a best practice approach to chemical choice and application to remove an infestation, and good flock and biosecurity management to prevent reinfestation.

The management of lice on-farm is underway against a backdrop of:

- Gradual development of resistance to chemicals by insects. Resistance to the synthetic pyrethroids is wide-spread resistance, and there is known resistance to diflubenzuron and triflumuron

- Spreading of chemical resistance amongst flocks

- Pressure on fabric manufacturers and retailers to scrutinise processors' use of chemicals

- Increased scrutiny of the on-farm environment

- Increasing scrutiny of on farm health and safety

- Increasing scrutiny of animal welfare.

Through LiceBoss, AWI provides Australian woolgrowers with tools for best practice lice control to minimise woolgrowers' costs and chemical use and improve clip quality. LiceBoss offers specific information about all aspects of lice and their control and also useful decision tools on whether lice might be present, what products to use on different types of sheep and their residues and costs.

In addition, AWI funds research into new lice diagnostic methods and environmentally-friendly lice treatments.

Current and Recent AWI Projects

Nanotechnology

AWI has partnered with University of Queensland to research the development of nano-encapsuled formulations of available blowfly and lice chemical treatments to extend the active period of the chemical.

Nanotechnology offers a means of providing extended protection of sheep against flystrike and lice This project is designing and testing unique silica nanocapsule formulations with spikes on the particle surface and purpose-designed release characteristics to give prolonged periods of protection against flystrike and lice, with minimal residues and off-target effects. This will provide new, labour efficient, options for managing flystrike in unmulesed sheep and countering resistance in sheep blowflies and lice.

Find more information on this project here.

WORM MANAGEMENT

The increasing resistance of worm and liver fluke populations to a range of drenches is a threat to the health and welfare of the Australian sheep flock. Internal parasites (worms and liver fluke) cost the Australian sheep industry an estimated $436m per year. This cost includes mortalities and production losses (reduced wool cut, stained wool, lowered staple strength), as well as the direct costs of control (mainly drenches and labour).

Resistance by worms to the "white" and "clear" drench groups is long established. Resistance to the macrocyclic lactones or MLs (the "mectins") is now also wide-spread. The continuing problem of selection for resistance requires the integration of non-chemical parasite management with the judicious use of chemicals, despite the promise of new drench groups on the market.

Through WormBoss, AWI provides Australian woolgrowers with tools for best practice worm control to minimise woolgrowers' costs and chemical use and improve clip quality. WormBoss offers specific information about all aspects of worms and their control and also useful decision tools to help solve your worm problem and what products to use. It includes regionalised worm control programs, Drench Decision Guides by region, contacts for advisors and a drench search.

Scouring and dags are common, widespread and costly on Australian sheep properties. While often attributed to worm infection, there are many causes of scouring and consequent dag formation. An AWI-funded review of the costs, reasons for and prevention of dag in sheep resulted in the development and distribution of a factsheet for woolgrowers and comprehensive manual for their advisors, including recommendations for the prevention of dags.

AWI is addressing the problems of internal parasites and scouring in two ways:

- Better use of existing technologies.

- New products and practices.

Current and Recent AWI Projects

Better use of existing technologies

AWI has invested in a number of on-farm trials with woolgrower groups to increase the understanding and encourage the adoption of improved worm control programs. The trials have involved assisting woolgrowers to undertake Faecal Worm Egg Count (WEC) tests and Faecal Egg Count Reduction Tests (FECRTs) so they can get an understanding of the magnitude of worm problems on their property and any associated resistance issues to worm control treatments. The woolgrowers are then provided with recommendations and support on best practice worm control programs specific to their property. These projects have the added benefit of enabling AWI to identify and understand any barriers to adoption, informing industry, including ParaBoss, extension and adoption activities.

New products and practices

Commercial sheep breeders, especially in the higher rainfall areas of Australia, increasingly want sheep that better resist parasite burdens. As a result, the number of ram breeders offering rams with genetic information about worm resistance is also increasing. An Australian Sheep Breeding Value (ASBV) for WEC has been available for sheep breeders since 2009. WEC ASBVs are the measure that breeders use when choosing rams for worm resistance. Sheep that are more resistant to worms are able to

- prevent more worm larvae from establishing and maturing

- suppress the egg laying of worms that do mature

As ram breeders have made genetic gains it has become harder to meet the minimum level of worms required to obtain a good assessment. The level required can also impact on the growth rate and condition of the animals. A new method, the mini-FLOTAC, of assessing worm egg counts, which presents a superior sensitivity compared to the current method, is being trialed.

INSECTICIDE RESISTANCE

The development of insecticide resistance allows individual insects to survive an exposure to insecticide that would kill individuals from a 'normal' population, and the more frequent the exposure of an insect to insecticide the faster resistance will develop.

We know that resistance to chemicals is increasing and so it is important for woolgrowers to adopt chemical resistance management strategies. There are a number of management strategies that sheep producers can adopt to minimise the degree of resistance, or at least delay its development.

- Adopt an integrated pest management strategy that incorporates non-chemical controls such as genetic selection and timing of shearing and crutching to reduce the reliance on chemicals.

- Only use insecticides when absolutely necessary.

- If treatment is needed, make sure it is applied effectively - do it right, once!

- Know which insecticides belong to which insecticide class. If treatments for lice and flystrike are deemed necessary, use different insecticides and appropriate classes for each pest. Use the FlyBoss tools to ensure that you are using different classes of chemical for flystrike and lice treatment.

- Use insecticides from different classes for treating and preventing flystrike. This is particularly important if relying on insecticides to kill larvae on flystruck sheep. It is important to break the cycle and ensure maggots on struck sheep do not survive. Non-insecticidal methods are more reliable than flystrike dressings for this purpose - dressings are mainly to prevent re-strike.

- Be aware that resistance to one insecticide may cause a cross-resistance to another related insecticide.

- As with all chemical treatments, follow the label directions and keep a record of the product (including batch number), dose rate, date of treatment and mob treated, for future reference.

For more information on insecticide resistance, visit theFlyBoss webpage.

Resisting resistance

Surveys are showing concerning levels of resistance to some flystrike prevention options.

Hear head of research at AWI Dr Jane Littlejohn discuss options and where to from here.

LISTEN NOW

Lice Memory Tool Research Design

Source: https://www.wool.com/sheep/welfare/flies-lice-worms/

Posted by: rickshembill.blogspot.com

0 Response to "Lice Memory Tool Research Design"

Post a Comment